Contents

Summary

Voltaplex Energy provides cutting-edge lithium-ion energy total solutions. Our mission is to foster the clean energy revolution by creating the most efficient marketplace in the world for lithium-ion cells and packs. Our consortium of partners permits a unique full-stack lithium-ion supply chain. Core competencies in quality control and customer support ensure a safe and easy client experience every time.

We are a low-cost solution

We understand how important cost per kilowatt hour is to our clients. That’s why we focus our manufacturing in China’s lithium-ion center, the Pearl River Delta. Component manufacturers, assembly facilities and supporting industries are all situated closely together, ensuring the lowest transport, material, and labor costs. Our consortium participates in bulk cell purchasing to drive cell cost lower for all clients.

Know what you are paying for:

- Request a Bill of Materials (BOM) during the order for full pricing transparency.

- Do not pay extra for battery pack tests. All of our battery packs undergo testing and we provide up to twenty age cycle reports free of charge.

- Guarantee Lot, have us perform voltage and impedance grading, or age cycle test and grade capacity on cells intended for assembly into battery packs.

What we believe

We enable the easiest integration of new and existing devices with low-cost lithium-ion technology.

Why Lithium-ion?

Once only powering laptops and specialty applications, lithium-ion batteries are now applicable to power almost anything. From consumer electronics (CE) to automotive and grid applications, the possibilities seem endless. And they might be – with the decreasing cost per kilowatt hour, lithium-ion along with solar and other clean energy technologies are revitalizing the way we store and use energy.

At Voltaplex, we believe such lithium-ion and research into new cutting-edge technologies will pave the way to a clean energy future.

After years of serving both startups and large industrial partners, we identified several problems that we felt were serious enough to commit effort to solve.

For any industry

We have powered products featured on BBC, Forbes, and more, while our clients include globally recognized brands and leading universities and laboratories. Our batteries have powered submarines, spacecraft, and everything in-between. Our core competency is in the large-scale manufacturing of small to medium format lithium-ion battery packs. Some industries we supply include home energy storage, electric vehicles, medicine, military, computing, power tools, robotics, sensors, and more. While we are primarily a large-scale B2B company, we also dedicate support for pioneering startups.

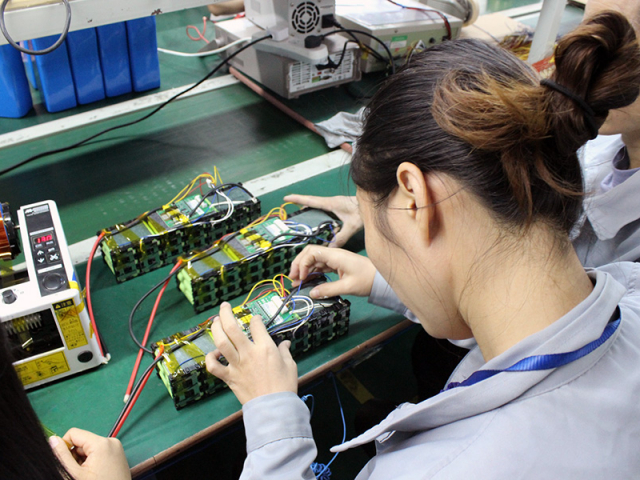

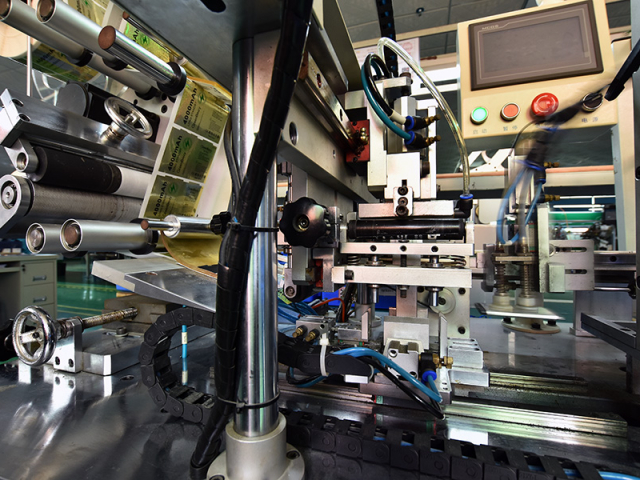

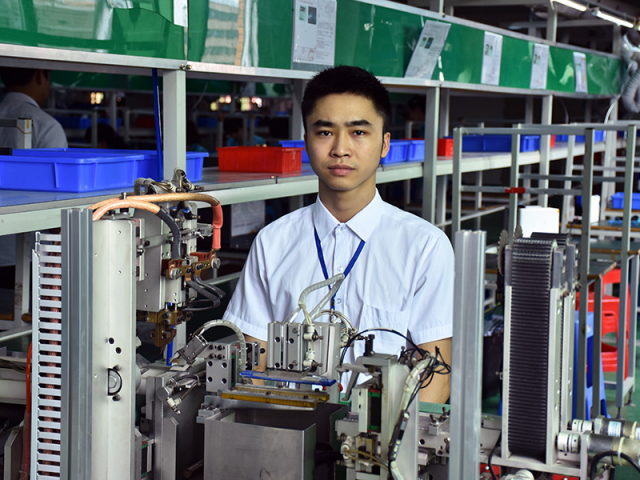

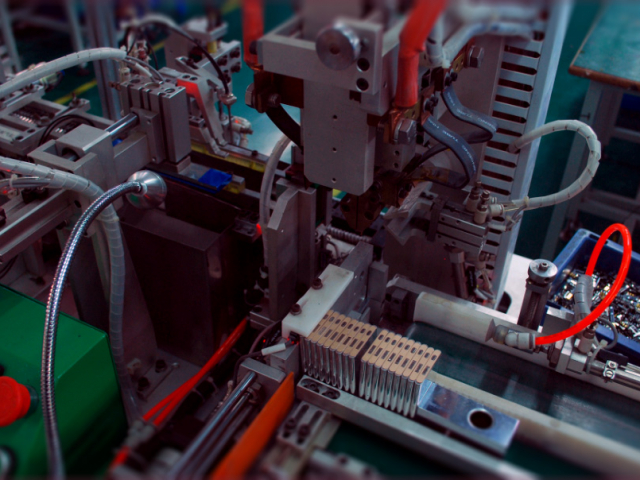

Manufacturing (assembly) 10-step process gallery

Factory brief

Our main factory in Dongguan, China provides battery pack assembly and testing.

| Type | Battery cell and battery pack assembly |

| Factory size | 6500m² |

| Founding date | 2005 |

| Operating workers | 400 more than |

| Office clerks | 40 more than |

| Certificates passed | ISO9001: 2008, BIS, UL, CE, ROHS, UN38.3 test, and others |

Our manufacturing centers in Xiamen and Shenzhen provide additional services and the production of battery packs and cells, with over 50 years of combined experience in lithium-ion technology, no project is too big for us to handle.

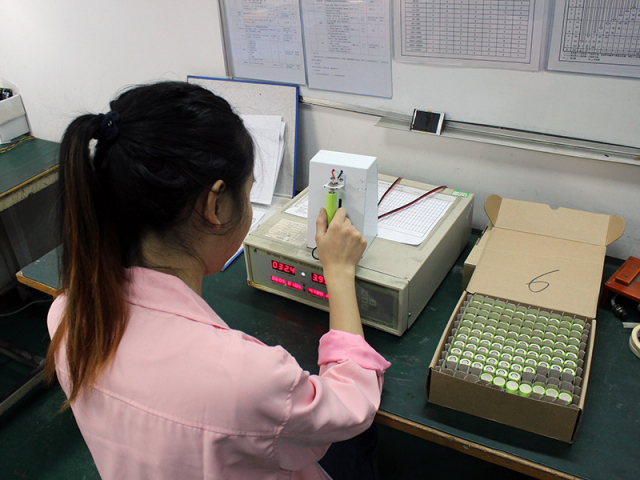

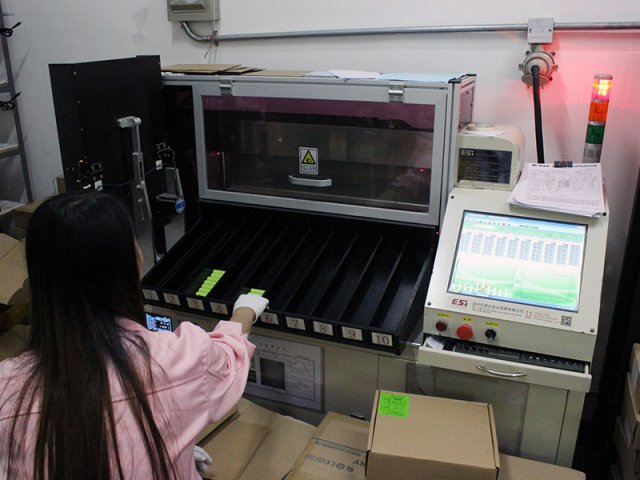

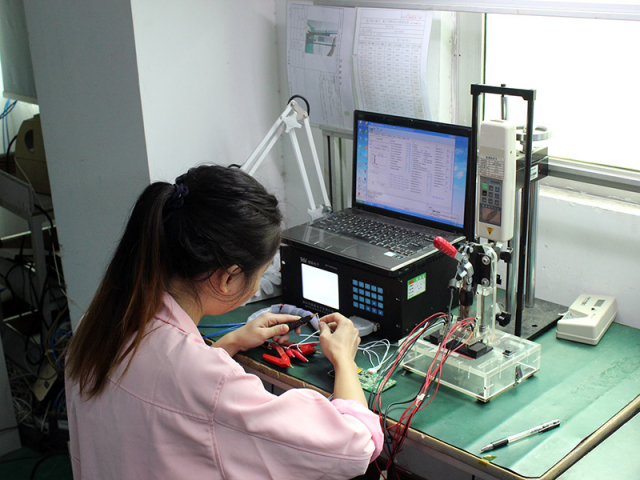

Quality control process

All our facilities utilize ISO 9001 process quality management system approach for all executed projects. This ensures we are able to identify, measure, control, and improve continually on our core processes leading to excellent business performance and customer satisfaction.

Drop-testing, puncture testing, and other custom tests and reports can be provided at request.

Purchasing process

All cells and component parts are purchased only from authorized manufacturers and distributors with supporting proof-of-purchase documentation where it may apply. Voltaplex has a zero-tolerance policy for counterfeit goods and parts.

Manufacturing process

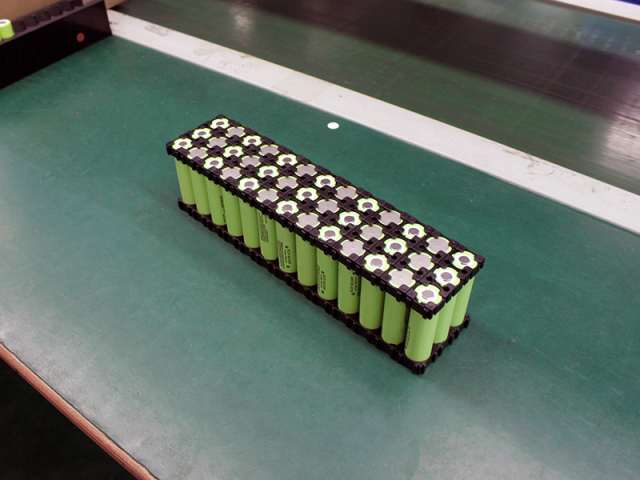

The typical manufacturing process for lithium-ion packs is as follows:

- Issuance of the specification sheet

- Component consolidation

- Assembly line scheduling

- Cell testing, cell matching, material matching

- PCB testing

- Glue and/or bracketing

- Spot welding nickel or other tabbing

- Spot welding PCB/PCM/BMS

- Application of insulation barley paper

- Welding wires, cables, connectors

- Application of temperature tape

- Application of insulation foam, insulation paper, and PVC heat shrink wrap or other casing

- Cycle age testing, visual inspection, photography, and other tests

- Packaging and issuance to the freight forwarder

Manufacturing lithium-ion battery packs

Original Equipment Manufacturer (OEM)

We manufacture battery packs based on your product designs and specifications.

Original Design Manufacturer (OEM)

We create your battery pack design and specifications based on a product idea brief you send us.

Purchasing high-quality lithium-ion cells

If you desire to prototype or assemble battery packs in-house we can source cutting-edge lithium-ion cells from leading manufacturers like Panasonic, Sanyo, LG, Samsung, Sony, BAK, Lishen, and others. We have a wide range of cells to choose from, including all sizes of cylindrical, polymer, prismatic, coin, flexible, and other cell types to fit your application. All of our cells are guaranteed 100% authentic and are backed by free replacement or refund warranty to meet performance specifications.