Choosing a custom battery pack manufacturer impacts production times and shapes how your systems perform under pressure. As more businesses require battery solutions that meet specific technical requirements, the need for experienced, precise manufacturers continues to expand.

And that’s where Voltaplex comes in.

Below, we’ve outlined how you can choose the perfect custom battery pack manufacturer for your business and operations. Soon, you’ll realize the top choice is much closer than you think.

Why Your Choice of Battery Pack Manufacturer Matters

Having a battery pack manufacturer affects every stage of production development, so finding one that aligns with your company and your values is critical.

These manufacturers influence how well a system integrates with your application, how efficiently it runs, and how long it lasts under load. A manufacturer must meet strict quality and safety requirements while maintaining consistency at scale.

Businesses that need custom battery solutions should prioritize proven expertise, application-specific engineering, and the ability to meet evolving technical demands across commercial and industrial markets.

The High Stakes of Powering Modern Devices

Modern electronic systems depend on high-density energy, precise battery management, and durability under environmental and mechanical stress.

Voltaplex builds custom lithium ion battery packs using high-grade Li-ion chemistries like Lithium Iron Phosphate (LFP) and Nickel Manganese Cobalt (NMC), balancing power and longevity based on application needs.

Every pack integrates safety features such as smart BMS technology and follows strict certifications, including UN38.3, UL, CE, and RoHS.

In other words, choosing a capable battery pack manufacturer ensures your system meets real-world demands without performance failures.

Key Qualities of a Top-Tier Custom Battery Pack Manufacturer

When looking for the right battery pack manufacturer for your operations, consider factors like design expertise, manufacturing capabilities, and certifications. This will help you make the best choice for your business, your values, and your customers. Here’s what to keep in mind when searching for a custom battery pack manufacturer that aligns with your needs.

Design Expertise

Voltaplex engineers build each custom lithium battery pack around the device’s operational profile, using lithium-ion chemistries like LFP and NMC to match exact voltage, current, and lifecycle needs.

Our expert team evaluates temperature limits, safety constraints, and space restrictions during development. Every custom battery solution begins with detailed modeling and prototyping to ensure performance aligns with functional requirements.

Having this kind of expert design reduces risk, improves integration, and supports long-term product success.

Manufacturing Capabilities

We proudly maintain complete control over the production of custom battery packs, with in-house assembly and automated processes that support scalability.

Our projects range from short-run prototypes to large-scale commercial and industrial systems manufacturing. We source top-tier lithium-ion cells and build packs to exact standards using precision spot welding, laser welding, and multi-layer BMS integration.

A capable battery pack manufacturer must handle technical complexity while maintaining consistency across volume.

Certifications and Compliance

Each Voltaplex custom battery pack complies with major regulatory and safety standards, including UN38.3, UL, CE, and RoHS.

The company manages certification requirements for its clients, ensuring every product meets legal and industry demands across global markets.

Battery safety involves more than components: it includes documented testing, traceability, and certification protocols. This level of compliance marks a serious and accountable manufacturer capable of supporting critical applications.

Custom Lithium Battery Pack Manufacturer Checklist: What to Ask

When choosing a custom lithium battery pack manufacturer, there are various questions you should ask yourself to ensure you align with your goals and functionality.

Having these conversations sets the foundation for a battery solution that performs reliably and supports your product’s success.

- How do you match lithium-ion chemistries to application requirements?

- What is your process for custom battery pack prototyping and testing?

- Can you support both low-volume and high-volume production without delays?

- What certifications do your battery packs meet, and how are those documented?

- How do you manage BMS integration and safety feature implementation?

- What is your typical lead time for a fully custom lithium battery pack?

These questions help you identify a battery pack manufacturer with the technical expertise and operational consistency required to meet your needs.

Voltaplex vs. Other Battery Pack Manufacturers: What Sets Us Apart

Voltaplex approaches custom battery manufacturing with a level of technical control and transparency that most suppliers simply can’t match.

Our company’s proprietary Voltaplex Life 18650 cells deliver up to 1,000 cycles at 1C charge without degradation, tripling the typical lifespan of comparable lithium-ion cells.

Every Voltaplex project receives customized engineering attention, and exact pack configurations are built to meet thermal, mechanical, and electronic thresholds unique to the application and its needs.

At Voltaplex, we do not rely on third-party assembly or generic components; instead, we invest in unique tooling, in-house design teams, and direct quality assurance oversight. These practices ensure system reliability under stress, especially in commercial and industrial use cases where failure is not an option.

Real-World Applications of Custom Lithium Battery Packs Across Industries

Voltaplex delivers tailored battery solutions across diverse sectors, ensuring each pack meets the unique demands of its application.

These custom lithium battery packs power critical functions in industries where performance and reliability cannot be compromised:

- Medical Devices: Portable ventilators, diagnostic tools, and wearable monitors rely on compact packs with precise BMS control for life-critical power.

- Consumer Electronics: Smart home gadgets, portable speakers, and high-performance workflows demand small, reliable lithium packs with stable discharge profiles.

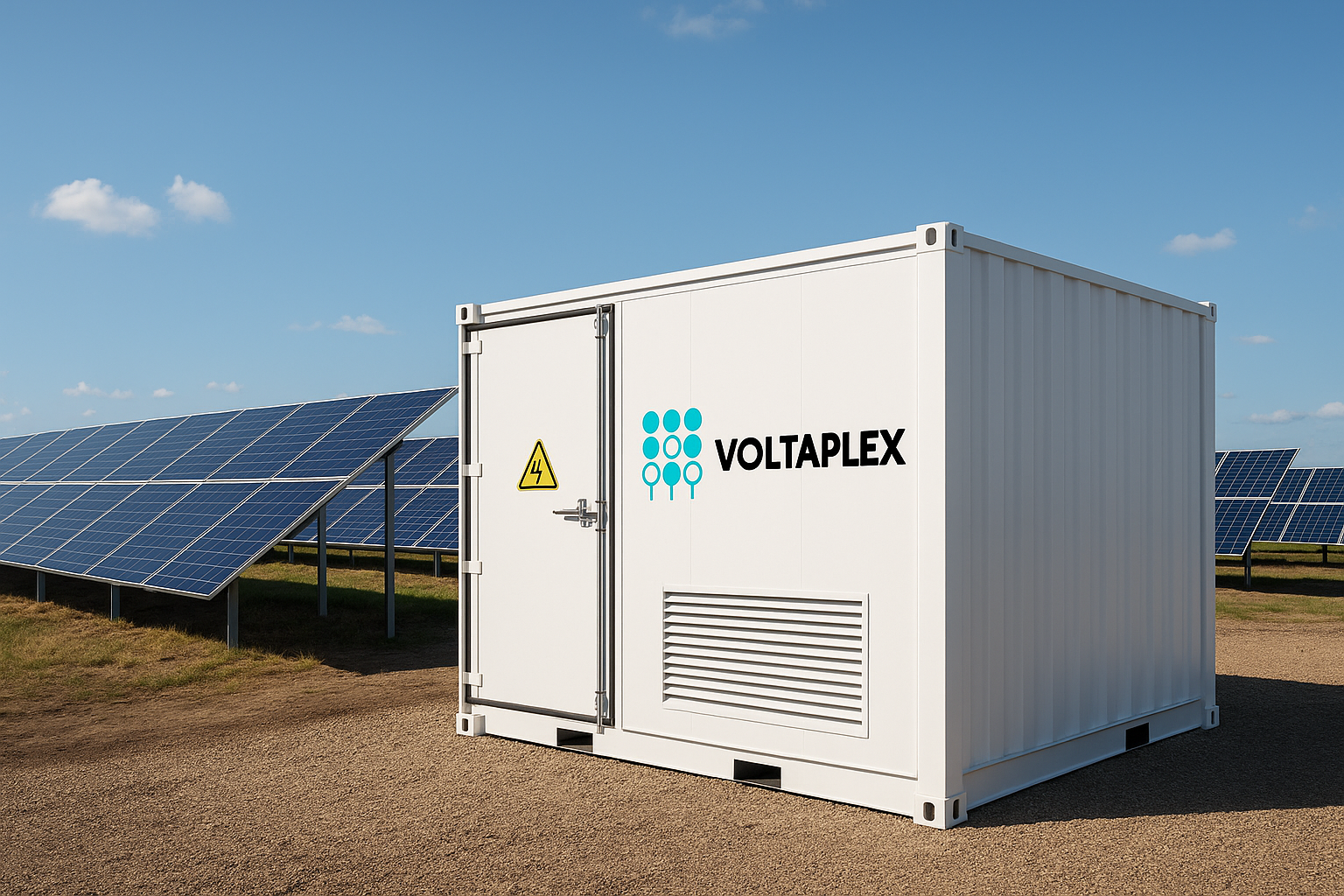

- Renewable Energy Systems: Solar storage arrays and off-grid systems use high-voltage lithium battery packs to integrate energy efficiently and reduce thermal losses.

- Electric Vehicles (EVs): Custom EV battery packs deliver high energy density and rapid discharge capabilities while maintaining thermal and safety performance.

All of these examples illustrate just how adaptable a custom battery pack manufacturer like Voltaplex can be, no matter your field of work.

Build Your Custom Battery Solution with Voltaplex

Voltaplex supports companies at every stage of development, from concept to production, offering precise, application-specific battery pack solutions backed by real engineering expertise.

If you’re looking for a custom battery pack manufacturer with proven capabilities and full certification support, request a quote and see how Voltaplex can power your next project.

Request a QuoteFAQs About Custom Battery Pack Manufacturers

Can Voltaplex create custom lithium-ion packs for harsh or high-demand environments?

Yes! Voltaplex builds battery packs for extreme conditions, including high temperatures, mechanical vibration, and continuous load demands. Packs are configured using appropriate lithium-ion chemistries, reinforced housing, and advanced BMS to ensure safety and stability.

What is the typical lead time for a custom battery pack from Voltaplex?

Lead times vary based on design complexity and production volume. For most custom battery pack projects, the client can expect timelines ranging from four to eight weeks from final design approval.

Can Voltaplex assist with international regulatory compliance?

Yes, Voltaplex supports clients through the full compliance process, including documentation and testing for certifications. This includes regulatory preparation for global shipping and product launch, which reduces approval delays and ensures battery packs meet legal standards across target markets.